Technical Guide

Cross-Laminated Timber (CLT or X-LAM) is a wood panel typically consisting of three, five, or seven layers of dimensional timber oriented at right angles to one another and then glued to form structural panels with exceptional strength, dimensional stability, and rigidity. It is lightweight yet very strong and has superior acoustic, fire, seismic, and thermal properties.

CLT is also fast and easy to install, generating almost no waste onsite. It offers design flexibility and low environmental impacts. For these reasons, cross-laminated timber is proving to be a highly advantageous alternative to conventional materials like concrete, masonry, or steel, and is especially well suited to multi-storey construction.

Span Tables

Cross-Laminated Timber (CLT or X-LAM) is a wood panel typically consisting of three, five, or seven layers of dimensional timber oriented at right angles to one another and then glued to form structural panels with exceptional strength, dimensional stability, and rigidity. It is lightweight yet very strong and has superior acoustic, fire, seismic, and thermal properties.

CLT is also fast and easy to install, generating almost no waste onsite. It offers design flexibility and low environmental impacts. For these reasons, cross-laminated timber is proving to be a highly advantageous alternative to conventional materials like concrete, masonry, or steel, and is especially well suited to multi-storey construction.

Surface Quality

Wood as a natural material is highly varied in its structure and has many natural characteristics. Often such characteristics can impair its visual appearance. Common visual characteristics are knots, annual rings and fissures. The surface appearance of XLAM South Africa cross-laminated timber panels is dependent on the surface type specified:

- Visual Quality (VQ) – the surface lamellae are planed and sanded. At a moisture content of 15% +/- 2% a maximum gap width of 2mm between the lamellae is permitted. The edges of all VQ panels are chamfered as standard.

- Industrial Visual Quality (IVQ) – the surface lamellae are planed and lightly sanded. At a moisture content of 15% +/- 2% a maximum gap width of 4mm between the lamellae is permitted.

- Non-Visual Quality (NVQ) – NVQ panels will not be provided for visual surfaces unless specifically requested by the client. Unprepared NVQ surfaces are not suitable for the application of painted visual grade finishes.

The perception of the surface finishes above is subjective and may lead to widely differing interpretations on what constitutes an acceptable finish. End-grain can only be provided as a non-visual grade finish. Sample panels representing the above surface finishes are available on request.

Fire Safety

CLT can be designed to accommodate substantial fire resistance and unlike steel remains structurally stable when subjected to high temperatures. CLT panels can be produced with fire resistances of 30, 60 and 90 minutes. Mass timber is proven to be a safe option for use in any occupancy class.

XLAM South Africa has undertaken fire tests which confirm the result of the many CLT burn tests that have been done worldwide.

Specifications

XLAM South Africa manufactures Cross laminated timber is according to the SANS8892 specifications using FSC certified sustainable timber.

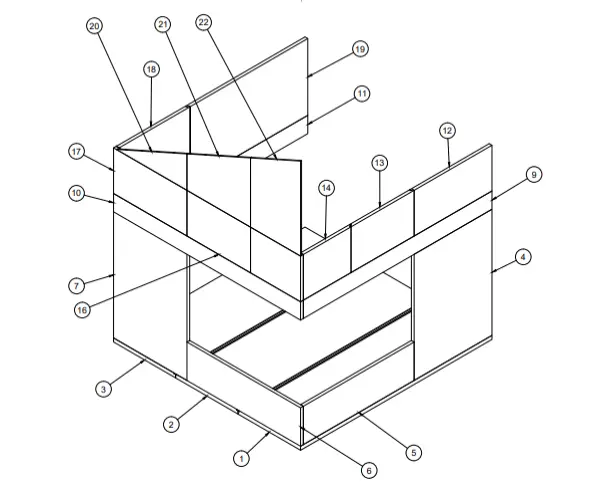

Cross Laminated Timber is a large-format, solid timber panel (with multi-layered, crosswise cross-section lay-up.)

Finger-jointed and planed lamellas are loosely laid next to each other and the flat surfaces of the layers glued at right angles to one another. To avoid uncontrolled stress cracks, the narrow sides are not glued, but we are able to glue for visual quality panels. The layers are pushed laterally to dimension before applying the pressure (8000kg /m2) in order to obtain a gap-free surface.

Lengths to max 8.25 m

Widths to max 2.70 m

Thicknesses 45 to 210 mm

Standard widths 1.20 m /1.80 m /2.10 m /2.40 m/2.60 m

Production is done in accordance with the draft SANS 8892 – Standard for performance rated Cross Laminated Timber.

XLAM South Africa is also FSC® chain of custody certified, which is an assurance that products are a sustainable resource.

Slash Pine (Pinus Elliotti)

Monterey Pine (Pinus Radiata)

Blue Gum / Flooded Gum (Eucalyptis Saligna Grandis)

PUR Adhesives to SANS 10183-2 Approved for the gluing of load–bearing timber components .

Approx. 480 kg/m3 for determination of the transport weight

5 kN/m3 according to EN 1991-1-1:2002 for static calculations

15% (± 2%)

II to panel plane 0.01% per% change in moisture content

= to panel plane 0.20% per% change in moisture content

Airtight from a panel thickness of 90 mm

30, 60, 90 and 120 minutes achievable depending on panel build up and treatment.

The average charring rate across several layers is for walls : 0.8 mm/min for ceilings : 0.9 mm/ min

-100mm CLT Panel:

R- Value: 0.83m2K/W (Timber panel only – excluding build up)

Available as untreated, surface treated or pressure impregnated.

Specialised treatments are available which aid in the preservation of the timber.

These treatments improve the durability of the timber and help prevent insect and fungal attack.

Advice on the specific treatments, and requirements, can be discussed during the design and specification process.

Further information on timber treatments, and the legal requirements, can be found on the website of the

South African Wood Preservers Association (www.sawpa.co.za)